The following projects are based on mechanical. This list shows the latest innovative projects which can be built by students to develop hands-on experience in areas related to/ using mechanical.

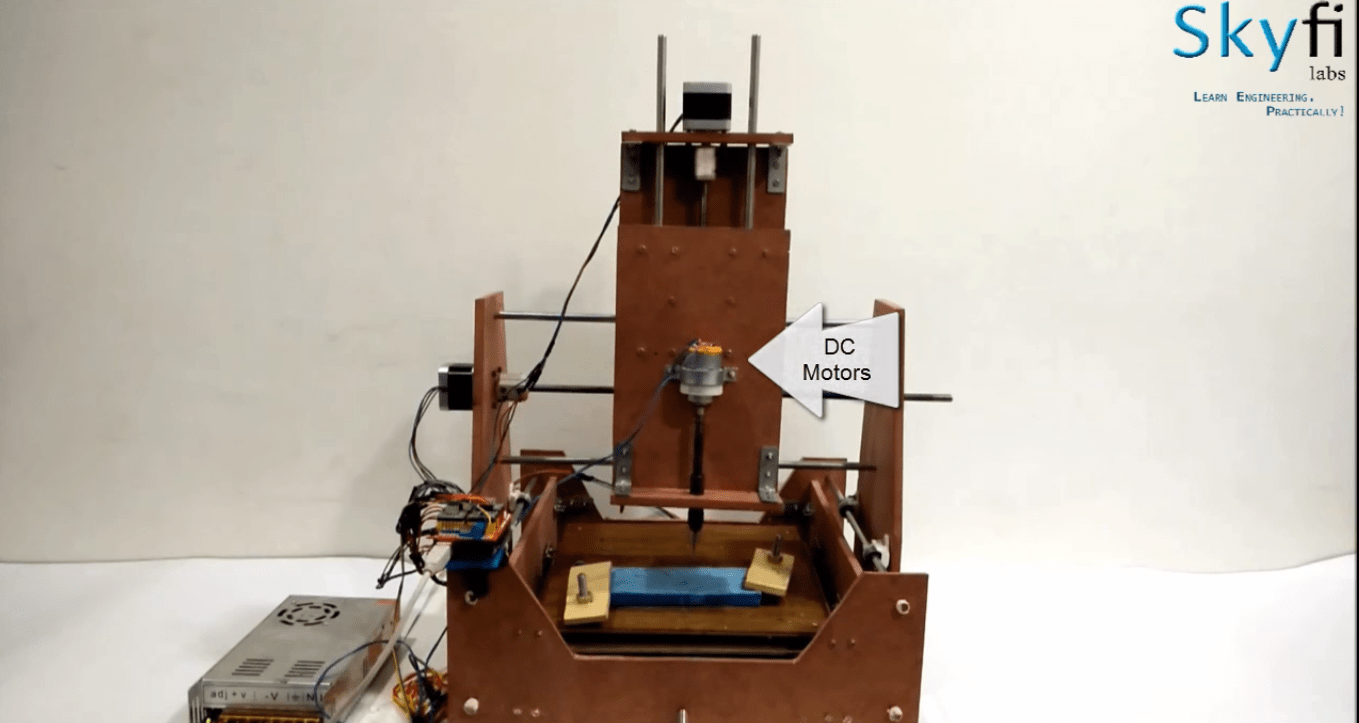

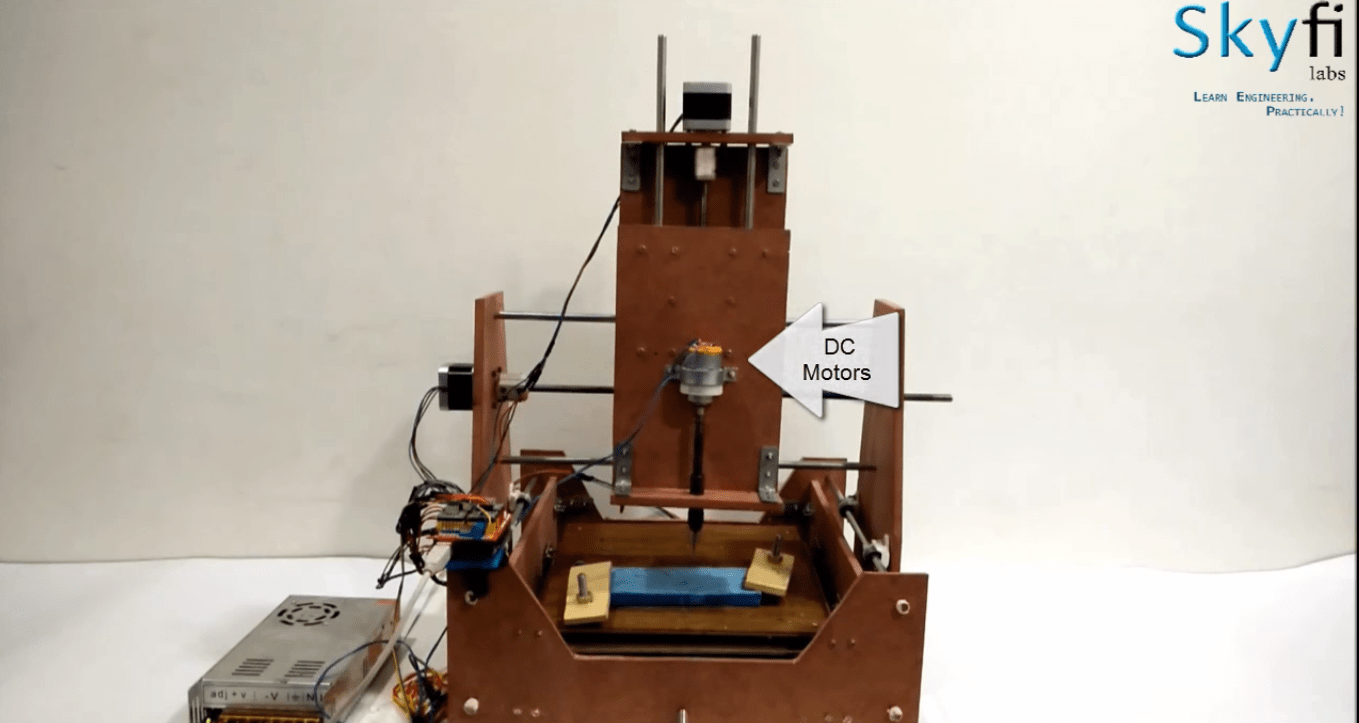

CNC (Computer Numerical Control) machines are used in manufacturing industries to develop a product with more accuracy. CNC machine uses a subtractive method to fabricate or develop a product. In this Arduino project, we are going to develop a miniature CNC machine which can be controlled using Arduino.

It is expensive to use physical experiments to get essential engineering data for designing is quite expensive. Getting engineering data of a fluid in motion, using Computational Fluid Dynamics (CFD) Simulations are relatively inexpensive. Costs are likely to be decreased as computational power has increased. So, using numerical methods to solve various flow problems is effective. In this project, you are going to solve a 1D Shock tube problem using Finite Volume Method.

The design and fabrication of a braking system is a difficult task. The application of brakes using vacuum in automobiles is a more difficult task in the initial stages of the work. But it has been successfully proved that such brake application is possible with the fail-safe condition. While implementing this idea on a heavy vehicle, it is better to replace the manually operated directional control valve with solenoid operated directional control valve to reduce driver effort and also it will work like a brake pedal switch. In this project, you will design and fabricate a vacuum braking system for a Train.

The development of many technologies that make our existence so comfortable has been intimately associated with the accessibility of suitable materials. In fact, early civilizations have been designated by the level of their materials development (Stone Age, Bronze Age, Iron Age). Thus, tens of thousands of different materials have evolved with rather specialized characteristics of materials. Many of our modern technologies require materials with unusual combinations of properties that cannot be met by the conventional metal alloys, Ceramics & Polymeric materials. In this project, you will get to know about a Functionally Graded Composite material which kind of solve the above problems. You will analyze this material using the Finite Element Method by modelling it using MATLAB.

There are mainly three different ways of heat transfer, Heat transfer by conduction, convection, and radiation. Conductive heat transfer is the basic mode of heat transfer, and it is comparatively easy to understand. In this project, you are going to solve a 2D conductive heat transfer problem involving variable conductivity. You will use numerical methods to solve this problem.

Want to develop practical skills on latest technologies? Checkout our latest projects and start learning for free

One of the most important factor, when you build anything is the material. Another important factor in civil engineering is cost. So, that the material should be economical. Soil or Earth is one of the cheaper material available nowadays.

Beams are descriptions of the building or civil engineering structural elements, but any structures such as motorized automobile frames, plane mechanisms, engine settings, and other or structural systems contain beam constructions that are intended to carry adjacent loads are analyzed

A flock of birds can easily bring down a billion-dollar aircraft. You might have read some news like aircraft is halted or crash happened because of a bird strike. In the US alone there were 142,000 bird strikes happened between 1990 and 2013 which killed 24 people and destroyed 64 civilian aeroplanes.

Birds are not only affecting the aviation industry but also other fields like Agriculture, Marine docks, Football grounds, etc.

In this drone project, we will try to figure out a solution to the above-mentioned problems caused by birds. Nowadays drones gained huge popularity because of the following features such as manoeuvrability, easy to control, low manufacturing cost, etc.

Here we are going to implement drones to scare/control the birds by producing ultrasonic sounds (Bird repellant) without making any harm to the birds as well as the environment.

Technological advancement has proved the impossible things as possible. Similarly, the recent innovations in UAV’s (Unmanned Aerial Vehicles) which are commonly known as drones paved the way for the newer way of transportation not only for carrying goods but also to carry humans from one place to another.

Increased usage of Automobiles like cars, bikes in the metro cities escalated the traffic and also increased pollution. To overcome both the issues here we are going to develop a drone project which can able to carry passengers from one place to another like a taxi.

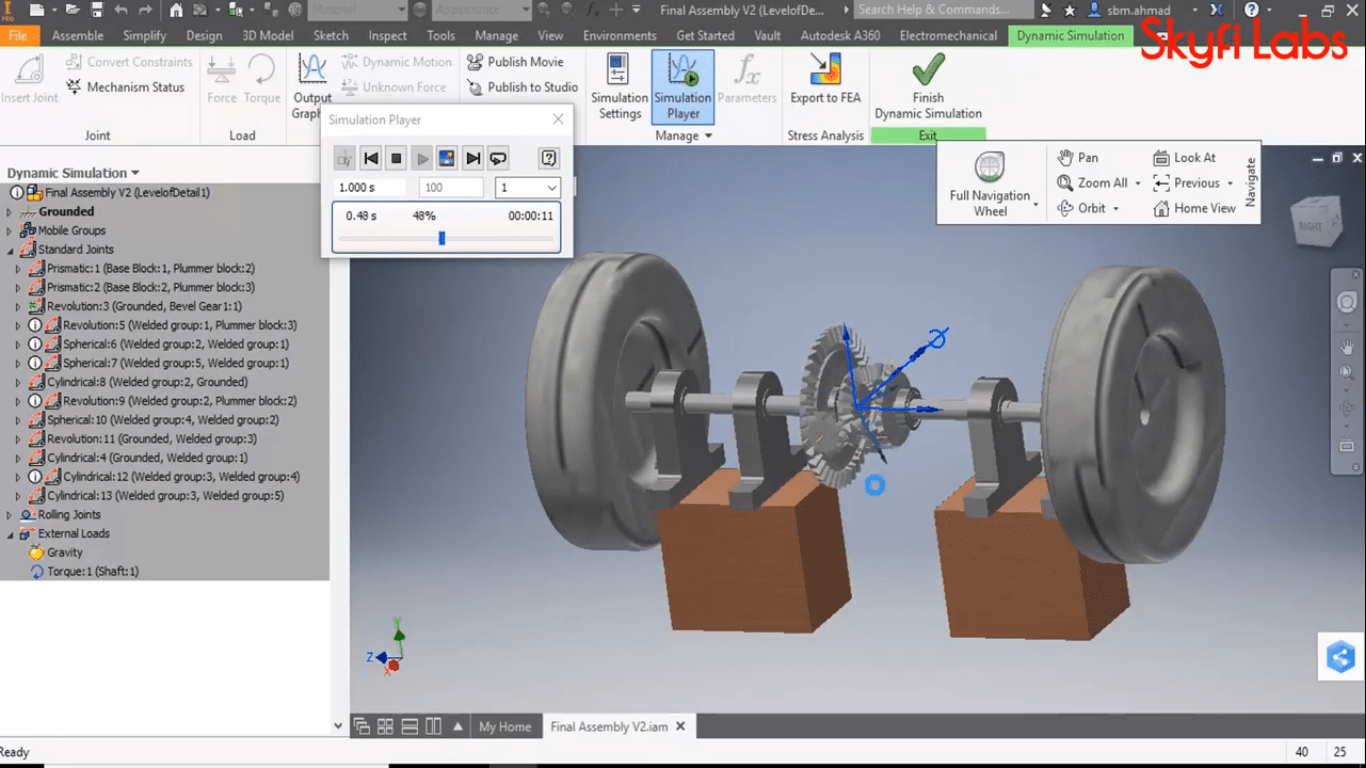

In this CAD project, you will learn to design and simulate a differential gear using Autodesk Inventor software. Autodesk Inventor software is widely used by design engineer professionals to create 2D and 3D models of various parts.

Earlier, manufacturers used to draw the 2D diagram of the product to be designed in different views - front view, side view, and top view. Then, they will start to manufacture and test the model. Here a lot of time is invested in manufacturing and testing. To overcome the above issue designers started using CAD software. CAD stands for Computer-Aided Design which is used to design, test and analyze the model.

CAD (Computer Aided Designing) is the process of making a 2D or 3D design of a product using the design software which makes designing and upgrading the product design faster compared to the manual drawing.

In this CAD project, we are going to use Autodesk Inventor software to design a Gear train assembly. Autodesk Inventor is a 3D CAD software that enables the user to design, simulate, visualize and create documentation for a product.

CATIA abbreviates to Computer-Aided Three-dimensional Interactive Application which is best suited for operations like CAD (Computer Aided Designing), CAM (Computer-Aided Manufacturing), PLM and 3D design. In this article, we will make a mechanical design and assembly of universal coupling using CATIA software. While building this project you will be introduced to various concepts of CATIA such as part design, Mechanism design, sheet metal and surface modelling.

Universal coupling or U-Joint or Universal Joint shaft is used to transmit the power through shafts by connecting the shafts in different angles. Which also allows the rear axle to move up and down freely without affecting power transmission. Universal Joints are found in transmission shafts of automobiles, industrial motors, propeller shafts, power transmission shaft of helicopter blades, etc.

In this CFD project, you will use ANSYS to analyse the fluid flow and heat transfer in a mixing elbow. Mixing elbow is used in piping systems of power plants and process industries to find the flow field and temperature field in the region of the mixing section which helps to fix the position of inlet pipes.

Before starting the project here is an overview of the problem which we are going to solve - Now a cold fluid (20C) is going to enter through the large inlet and it is going to get mixed with the warmer fluid (40C) which enters through a smaller inlet at the elbow. For the flow at the large inlet, the Reynolds number is 50,800, hence the turbulent flow model will be needed.

In this MATLAB project, we will model and simulate a Hybrid electric vehicle using MATLAB/Simulink and ADAMS.

Recent days air pollution has reached the maximum limit in most of the cities, the major part of the pollution is produced by the automobiles. Because automobiles burn gasoline to convert chemical energy to kinetic energy. To overcome this problem electric vehicles are introduced. Electric vehicles have an advantage of less emission or almost zero-emission when compared to the gasoline-powered vehicles. But electrical vehicles range is very less compared to gasoline/petrol vehicles. Because the battery used in electric vehicles can’t store more energy.

After the advancement in technology, the hybrid vehicles are developed which combines the advantage of both electric and gasoline vehicles. Where fuel is burnt by an ic engine to charge the battery with the help of a generator and the stored energy from the battery is used to run the vehicle. There are two hybrid systems: Parallel hybrid and Series hybrid.

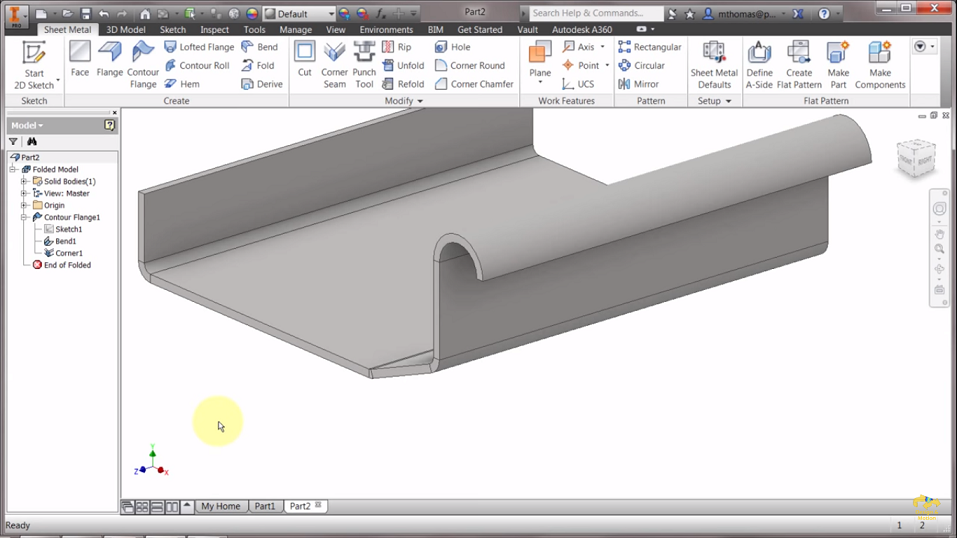

Sheet metal is one of the most common raw material used by manufacturing industries to make various components. It is a type of metal which is shaped into various components by cutting, punching, stamping and bending. Sheet metal is known for its durability and easy handling. Using sheet metal you can make low volume prototype and can execute the fabrication more effective for high volume production runs.

In this CAD project, you will use Autodesk Inventor to create a contour flange using sheet metal design concepts with the help of tools such as line, spline, arc, etc.

Solidworks is a CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) software used to perform solid modelling. In this article, you will be introduced to various concepts such as part design, mechanism design, sheet metal and surface modelling.

Crowd control and monitoring is a difficult task for the police forces if the strength of the crowd is huge. Usually, the police will use tear gases to disperse the crowds in uncontrolled situations but during this process, the police might be injured to avoid such situations we can use the drone to control the crowds.

With the advancement in technologies, the usage of drones increased a lot. In this drone project, we will propose a solution to this problem.

The use of Unmanned Aerial Vehicles (UAV) and Unmanned Underwater Vehicles (UUV) in both military and commercial sectors have expanded greatly in recent years. The advancement in technologies paved a way for developing a single vehicle which is capable of working on both Air and underwater environment.

In this drone project, you are going to develop a fixed-wing drone that can able to fly like an aircraft and swim like a fish.

Recent advancement in aerospace and automobile paved the way for new gadgets. Hoverbike is one such innovation which combines the technology of helicopter and bike to make the transportation better.

In this aeronautical project, we will discuss the design consideration, applications and materials used to build the hoverbike. Also, you will learn to build a miniature hoverbike.

Drones are becoming more popular than ever due to their unimaginable applications and fascinating modifications. Along with their applications, the manufacturing cost of the drones also will increase. To overcome the above problem in this project idea, we are going to propose a solution. The best way to reduce the cost is by reducing the components used.

Modular drones are aerial vehicles which can be modified on the go. A single drone can be modified and used for various purposes. For example, you want the drone to capture high-quality videos - use an HD camera mod or you want to use the drone to convey information - fix the speaker mod or you want the drone to display something - attach the screen mod.

As we are advancing in technology it is necessary to find a newer method of energy generation with minimal damage to the environment. The wind is renewable source energy which will not pollute the environment. The energy generated from the wind almost fulfils the energy requirement of most of the households. But wind turbines have drawbacks like high implementation cost and difficulty in the transportation of components.

Airborne wind energy generation is the only solution to solve the problem. Here the turbine is placed airborne and the power generated is transmitted to the ground with the help of power cables. This saves a lot of cost in the implementation and transportation compared to the conventional wind turbine system.

In this aeronautical project, we are going to develop an airborne wind energy system using lighter than air aircraft.

ADAMS is a multi-body dynamics simulation software used by industries to test their product before manufacturing it. In this tutorial, we will discuss how to perform a simulation of Pick and Place robot in MSC ADAMS.

Robots created a revolution in the industry field by automating the manufacturing process and making the output fast. Pick and Place robot is one such robot which is used in industries like automobile, aerospace, embedded system, etc. to speed up the manufacturing process in the assembly line.

The Pick and Place robot have to withstand various loads on its joints and components while functioning. After manufacturing then testing the components will increase the production cost. So with the help of ADAMS multibody simulation software, we are going to simulate the model to find the loads acting on its joints.

Generating power from winds is the purest form of energy generation method when compared to other energy generation methods like thermal powerplant, nuclear power plant, etc. It also doesn’t affect the atmosphere by releasing harmful gases like Carbon dioxide or Carbon monoxide. But for generating electricity from the wind needs a huge setup such as blades, pillars, generators, etc. It also requires a lot of maintenance after the implementation. The cost of setting up the wind turbine is also very high.

In this aeronautical project idea, we will propose an innovative solution to generate electricity from the wind. We are going to develop an Airborne wind energy system to replace the traditional windmills.

Drones are the major innovation of this century which is widely used for various applications. They already proved their ability in various fields. Here we are going to use tethered drones to generate power from the wind. Here the drones are launched in the air and positioned at an altitude of 600-1000 feet. At this altitude, the turbulence of the wind will be less compared to the altitude where the conventional wind turbine is positioned.

ADAMS is a simulation software widely used by OEMs to test their product by performing various multi-body dynamic simulation to identify the errors and defects. This helps the manufactures to reduce the cost of production. In this tutorial, we will perform a simulation for IC Engine valve mechanism using MSC ADAMS software.

IC engine or Internal combustion engines are the prime movers of the automobile. It converts the heat into work thus the IC engine is also called heat engine. In order to increase the efficiency of the engine, the inlet and exhaust valves should open and close properly. Due to the rapid combustion process, the force exerted over the valve will be more. The actual force exerted over the valve will be difficult to calculate so ADAMS software is used to detect the force exerted on the valves.

Model-based designing is the new future of the IT world as it helps the researchers to move their design and tasks into the desktop for better manipulation and calculation. A top expert in every field uses Simulink to perform various operations to check whether the system works properly. While using Simulink, MATLAB is considered to be good as it helps in analyzing real data and situations.

Overview

Bluetooth is a wireless communication device used to transfer data from one device to another. It is the simplest way to transfer data using port addresses of the devices. Nowadays, Bluetooth is installed in every device and anyone uses it simply. Bluetooth with MATLAB is the new way of communicating efficiently between devices. We will use MATLAB on one side and Arduino on the other side.

In this MATLAB project, we will establish a secure connection between the different devices using these two tactics. Well, there are many ways to make the connection but we will see the simplest one.

The main purpose of this MATLAB project is to identify the Pedestrians on the road. Since it is somehow difficult to identify the pedestrians during day and nights. This helps us to find a solution. By using Matlab software the project is handled. Implementation of this project brought to bring a driverless car. Developing this project makes more importance in the driverless car where it detects the pedestrians and counter the car. Nowadays this became more important in auto motives to improve the safety system.

Drones or Unmanned Aerial vehicles are used widely to do various things in fields like logistics, rescue, surveillance, inspection, and many more. More innovations are happening in the structure of the aerial vehicles to reduce the size of the aerial robot to make it more agile. Multirotors are more stable than fixed-wing but the size of the drone and the rotor positioning make it inaccessible in small areas.

In this drone project, we will try to implement biomimicry design in aerial robots to solve the structural issue in accessing small areas. Aerial transformation is one way to solve the problem. Here we are going to implement a biomimicry design similar to snake with the help of multi-link structure. This provides the ability of multi-degree of freedom aerial transformation.

INTRODUCTION

A heat pipe is a latent gadget with an upper heat conductance. It is a closed emptied tube or office of varied shapes. Its internal surfaces are stock-still with a fine wick. Heat pipes are now used in a wide group of heat move-related applications. In this work, a two- dimensional limited part number- based model is created for the reproduction of heat channels to their resulting state where execution attributes. The limited- component models are developed in ANSYS programming to predict the temperature with the heat pipe. Some cases are discussed with various types of heat pipe divider materials, powerful warm of the wick, no-go heat transpiration at the evaporator, and working liquids. In all the cases, heat pipes are shown as areas, especially, evaporator, adiabatic and condenser areas. Reasonable material and heat conductivity would help for the heat pipe divider. Chosen heat transition at the evaporator section. At the condenser segment, the convective heat moves and is applied. In the adiabatic section, if no there is no condition, ANSYS treats the surface as adiabatic. At the point when all these conditions recreate the model, ANSYS programming produces good results.

Introduction:

The flywheel is a rotating mechanical device which is used to store rotational kinetic energy. They have a significant moment of inertia which resists change in rotational speed. In flywheel, as there is no conversion of energy from one form to another the efficiency of this tool is very high. Flywheels can also be named as mechanical batteries. The kinetic energy recovery system recovers the kinetic energy of a vehicle under braking or halting and stores this energy to be utilised when the vehicle is under movement. The loss of energy during braking is very high and the energy required during the start of the vehicle is less. Usually, during barking, the energy is lost in the form of heat or by producing some noise but when a flywheel is this energy can be reused by supplying this energy to the vehicle when it is started.

Introduction

Electricity is very important in our daily lives, we need it for various purposes. India is one of the largest producers and consumers of electricity. The demand for electricity is increasing. There is a need to produce electricity in a sustainable manner. The electricity should be renewable and efficient. About 70% of the electricity in our country is generated by thermal power plants. It is also important to produce electricity that is pollution-free and meets our daily demands. Electricity generator tiles could be a good source for producing electricity.

An executive segment is a mechanical framework that is associating the executive wheel to the system of the front wheels of a car. Pneumatic machinery consists of equipment and workings which use air power to do work. The air is controlled by control valves and dispersed through the cylinders. The notorious fame of pneumatic machinery is because of a very huge sum of power that can be transferred all the way through small tubes and flexible channels. Here, we will see how the pneumatic power steering system works using Solidworks.

Drones are Unmanned Aerial Vehicles that finds its applications in various fields from delivering packages to surveillance, agriculture and many more. In this drone project, we are going to develop an autonomous seed sowing drone that can be used to plant trees in both agricultural fields and forest.

With the help of tree planting drones, you can plant a large number of trees quickly in less time. Seed sowing drones can be used for reforestation to plant a large number of trees that are destroyed due to forest fire or natural calamities.

Farmers and environmental agencies are facing difficulties in planting the trees or sowing seeds in the field. This seed sowing drone provides an effective solution to solve the problem by sowing seeds quickly with more accuracy. These drones are operated in a swarm to cover the large area in less time.

INTRODUCTION:

It portrays a double side shaper machine utilizing a scotch burden system. A Shaper is a machine that is used for forming (metal evacuation) procedures on the workpiece. These days, Industries attempt to accomplish a high creation rate at a negligible measure of time, cost, and so on. The use of a double-side shaper machine wipes out most hindrances looked by a solitary side shaper. The fundamental position of a double-side shaper is that it diminishes time as well as creation cost. In this manner, it expands profitability. A Shaper is a kind of machine apparatus that utilizes direct relative movement between the workpiece and a solitary point cutting device to machine a direct device way. Its slice is comparable to that of a machine. This experiment can be easily carried out in Solidworks.

A device that controls the speed of the fluid flow, directions, and flow characteristics is a Nozzle. The nozzle is designed like a pipe with a non-uniform cross-section. This design helps in controlling the velocity, flow rate, pressure ratio, direction, etc.

Flow characteristics of the nozzle section can be varied with the variation in pressure difference at the outlet and the inlet sections.

A CD nozzle or convergent-divergent nozzle is shaped like a tube with two bulging ends and a narrow section in the middle. This structure/design gives a balanced shape for the nozzle. Nozzle speeds up hot, pressurized gas passing through it in the axial (thrust) direction, by converting the heat energy of the flow into kinetic energy. A CD nozzle is of most importance to increase the kinetic energy of the medium.

There’s a lot of pressure in improving the designs of internal combustion chambers. The engines of the next generation need to be light, small, powerful, and good adaptability, with the usage of less fuel and less pollution. To meet these competing requirements, innovative engine designs are drawn. The ability to analyze the performance of many engine designs has also become critical.

A computational fluid dynamics (CFD) modeling of the spray formation process in a Diesel engine, developed in ANSYS-FLUENT using its discrete phase modeling (DPM) capability and its IC-engine module. To know about the performance of an IC engine it is important to know the fluid’s interaction and also the moving parts of the engine.

In convection, heat is transferred from one body to another with a medium present between and the heat travels from the heated body to the medium and then to the cold body and because of which heat is transferred to the surroundings.

Density plays an important role in the heat transfer process as it does not follow the law of reflection and refraction.

{ BERL- Burner Engineering Research Laboratory }

In the case of non-premixed methane BERL combustor, there are two ports incorporated:

The portable devices which can provide energy anywhere are the batteries. Batteries are almost used in every sector starting from our cell phones to the vehicles in which we move. As the competition in producing batteries has increased, for a company to stay in this competition good working is important.

Simulating batteries is a difficult job because of their metaphysical nature and where they are applied. Only Ansys helps us in simulating batteries and also to create better battery designs for any application.

Market leaders for battery making depend on the purpose of the battery and the company which provides good safety, proper size, and at an affordable cost. Simulation for a battery depends on its application and the amount of charge needed and its performance.

In brakes, the main property is the thermal conductivity as a lot of heat is generated in the brakes when it is applied. So, the brakes must be strong enough to control or dissipate the heat and to stop the vehicle with minimum displacement in urgent situations.

The main property of the brake is that it should cool down rapidly to avoid any structural imbalances to the brakes and another thing is that it should clean itself automatically.

Disc brake slows the rotatory motion of the wheel by the abrasion of brakes pads onto the wheel. During braking, kinetic energy is converted into heat energy, which heats the air present in between the brakes by which the durability of the brakes increases.

Finite element analysis helps in numerically solving any engineering problem. FEA represents every engineering problem in a numerical way by which the solution to the problems can be known and whether the process is feasible or no can be known.

The unmanned Aerial Vehicle or Drone is one of the best innovations of mankind. From photography, surveillance, public safety, logistics, law enforcement, agriculture, and many other fields, drones are deployed to ease the work. Though the drone has a variety of advantages the major limitation is flight time. Even the advanced drones have a flight time of 30 minutes only.

In this drone project, we are going to solve this problem by developing a tethered drone. With tethered drones, the endurance of the flight is increased compared to free-flying drones.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

Want to develop practical skills on latest technologies? Checkout our latest projects and start learning for free

Join 250,000+ students from 36+ countries & develop practical skills by building projects

Get kits shipped in 24 hours. Build using online tutorials.

Stay up-to-date and build projects on latest technologies