The following projects are based on concrete. This list shows the latest innovative projects which can be built by students to develop hands-on experience in areas related to/ using concrete.

Fiber reinforced concrete (FRC) is a new structural material which is gaining increasing importance. Addition of fiber reinforcement in discrete form improves many engineering properties of concrete. Currently, very little research work is being conducted within the King-dom using this new material. The use of fibers eliminate the sudden failure characteristic of plain concrete beams. It increases stiffness, torsional strength, ductility, rotational capacity, and the number of cracks with less crack width. In conventionally reinforced concrete beams, fiber addition increases stiffness, and reduces deflection.

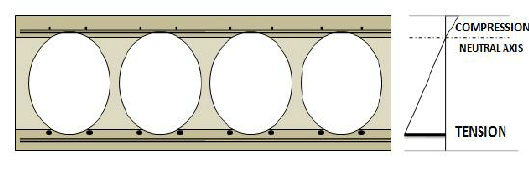

Retard-bonded prestressed concrete has been in use for twenty years and is a new and distinctive prestressed system. Mechanical and service property

Concrete is considered the world’s most used construction material. Typical concrete mixtures are comprised of water, sand, cement and an aggregate of rock. This civil project focuses on the coarse aggregate in concrete. Here you will replace the coarse aggregate by burn brick or Jhama brick and you will study the effect of salient parameters that affect the properties of Jhama class brick based concrete. You will also study the short-term mechanical and physical properties of fresh and hardened Jhama class brick based concrete.

It is known that wastage in India in the construction industry is as high as 30%. This is a large, yet relatively simple and straightforward challenge needs to be tackled by engineers. These wastages are activities that absorb man hours, resources and materials but create no value. In this project, you will use those waste materials to make something productive by making a concrete using recycled aggregate and fly ash. After making concrete you will compare the compressive as well as flexural strength characteristics of the concrete made through NMA and TSMA.

Concrete technology has undergone a rapid improvement in the last two decades and internal curing of concrete has gained popularity and is progressing steadily from the laboratory to field. Water consumption has also been an issue and the scarcity of water is increasing exponentially too.

Want to develop practical skills on latest technologies? Checkout our latest projects and start learning for free

The increased waste in the construction industry causes a major problem for disposal operation. The waste materials from construction activities are heavy in weight and occupy more storage space. In India out of 48 million tones of solid waste generated, construction waste make up 25%. Concrete and masonry waste can be recycled by sorting, crushing and sieving into recycled aggregates. This recycled aggregates can be used to make concrete for road construction, soil stabilization, etc. The re-use of waste material is an important factor in point of sustainability.

Cracks are a common phenomenon in concrete structures due to shrinkage. These cracks create a path for liquids and gases (contains harmful substances) into the concrete members. Reinforcement may get corroded if the liquids reach the steel reinforcement. So, it is necessary to take precautionary measures to end these cracks at the very beginning stage. Self-healing concrete is one of the ways to avoid the formation of cracks problem.

In recent years, there has been a great interest in improving the properties of concrete by involving various puzzolanic materials in the concrete mix.

One way or another, concrete structures always contributing pollutants for environmental pollutions. In heavy rainfall areas, the concrete pavements becoming a major source for water pollution.

With more technological advancement in the architecture industry, we are able to experience more new innovations every year.

The use of composite materials is a new trend in the construction sector. There are many reasons for this new adaption in the construction industry.

The disposal of waste materials is always been a major problem for environmental engineers. Solid waste has the most adverse effect on the environment compared to liquid waste.

The durability of existing concrete structures always depends upon the properties of hardened concrete. To find the safety of any existing concrete structures,

Bamboo is one of the oldest traditional building materials used by mankind. They are the largest members of the grass family and are the fastest-growing in the world.

Concrete is a foremost important material in the construction industry due to its vast applications. With the recent development in concrete technology, new and advanced types of concrete making methodologies are emerging.

Around 110,00,000 new vehicles are been added to Indian roads every year. Due to this, about 3 crores of tyres are been discarded by the vehicle users every year and causing a potential threat to the environment.

Compressive strength is the resistance of a material to break under compression. The compression test is usually performed in a universal testing machine. This varies from tabletop to large machines. To avoid large machines, we have introduced machine learning and automation in construction.

ANN (artificial neural network) is a huge architecture which has the capability of generalizing and learning from the data which is given in the form of exercises and examples from the humans. This ANN gives us a meaningful solution to problems if the input data isn’t correct or incomplete from the previous examples and experiences. This property makes ANN an outstanding tool for solving complex engineering problems.

People refer green concrete which is having the coloured pigment. But generally, the concrete which is environmentally friendly is called as green concrete. This concrete will use less energy for its production, and also emits less carbon dioxide than normal concrete. The concrete is mainly comprised of cement. The main component of the manufacturing of the cement is limestone (calcium Carbonate CaCO3). During the manufacturing of the cement the raw materials are heated about 800 – 1000 degree Celsius. Approximately 1kg of cement releases around 900gs of CO2 into the air.

There are many different types of concrete in the world. Each of the them are having added advantages and disadvantages when compared to each other.

For example, if concrete is made from the sulphate-resisting cement then it is good in resisting concrete from sulphate attacks but will not be good in strength as compared normal or traditional concrete.

Different concretes are been developed in the world for different purposes. Some of them are used under water some of them for rapid hardening, some of them in Ready mix concrete etc… one of them is this reactive concrete. This was first developed by P.Richard and in the early 1990’s. this RPC is prepared by replacing the ordinary concrete with quartz powder, silica fume. It has very high strength and also ductility. The compressive strength may vary from 250-810 Mpa.

Reactive concrete will have very fine powders such as sand, quartz, steel fibres, super plasticizer and cement. The quantities used are generally as follows: OPC – 1000, Water -18, Fine sand – 500, Silica Fume – 230, Quartz powder -390, Super plasticizer – 18, Steel fibers – 630 all the weights are in kg per cubic metre. And this mix give approximate strength of 800Mpa.

Requirements:

Knowledge of concrete technology.

Knowledge of Mix Design.

Cement

Sand

Quartz Powder

Silica Fume

Steel Fibers

Super Plasticizers

Test apparatus for the concrete (concrete lab can be used)

Project Implementation:

Software Requirements:

Advantages:

Disadvantages:

Conclusion:

This project is still in development stage and do more improvisation by adding or removing the materials used in it. If you want to make something new or learn something new regarding the concrete technology then you can do this project and experience it yourself.

Concrete is being used since very old times. It is used since roman age for the development, housing and infrastructure. But the materials used in the concrete is been not changed. Concrete is majorly made of the three components, cement which is a very fine powder and acts as binder, fine aggregate, which comprises of small and fine sand particles, Coarse aggregate, which comprises of large to medium pieces of the stone or gravel.

Concrete is thee majorly used material in the construction industry and it is also evident that it is one of the materials that are in the part of emitting the CO2 into the atmosphere.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

Want to develop practical skills on latest technologies? Checkout our latest projects and start learning for free

Join 250,000+ students from 36+ countries & develop practical skills by building projects

Get kits shipped in 24 hours. Build using online tutorials.

Stay up-to-date and build projects on latest technologies