The following projects are based on cfd. This list shows the latest innovative projects which can be built by students to develop hands-on experience in areas related to/ using cfd.

As well all know that it was the wright bros who gave the first successful manned flight to the world, and there are better proofs that eight years earlier to wright bros, an Indian Sanskrit scholar S B Talpade designed a basic aircraft called marutshakti, unmanned aerial vehicle at Chowpatty beach in Bombay, crediting him the first creator of an aircraft in modern times. He used Vedic technology for designing the aircraft.

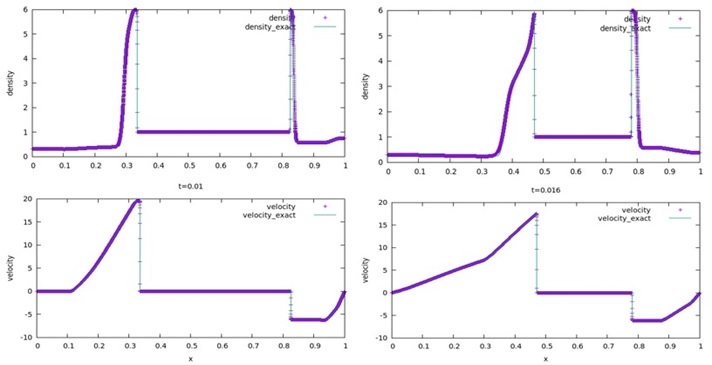

It is expensive to use physical experiments to get essential engineering data for designing is quite expensive. Getting engineering data of a fluid in motion, using Computational Fluid Dynamics (CFD) Simulations are relatively inexpensive. Costs are likely to be decreased as computational power has increased. So, using numerical methods to solve various flow problems is effective. In this project, you are going to solve a 1D Shock tube problem using Finite Volume Method.

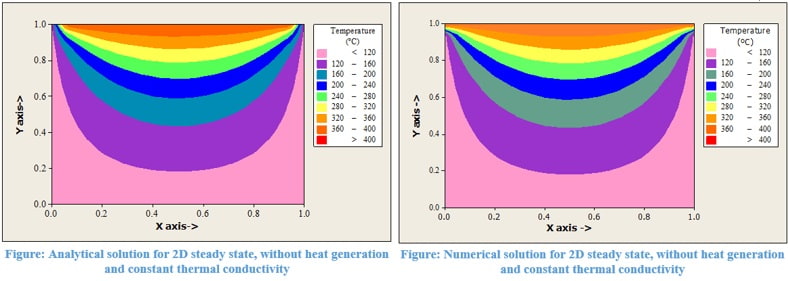

All the engineering devices we use involves the conversion of energy. In this process, a lot of heat released to the surroundings as a part of energy loss. The efficiency of any device can be increased by minimizing loss due to heat transfer. That’s why a lot of research going on around the world in the field of heat transfer. To solve real-life heat transfer problems Numerical methods are preferred, because of less time consumption, ease, and convenience. To get hands-on experience on numerical methods, here you are going to solve the Two-Dimensional flat plate problem with Constant conductivity heat transfer by using Numerical methods.

The Aerospace industry is increasingly relying on advanced numerical flow simulation tools for analyzing all the components of aircraft. The main part which helps in producing lift is wings. So, the shape of the aerofoil should be designed in such a manner so that maximum lift can be achieved. In this project, you are going to work on a standard NACA airfoil and analyze it using finite element volume tool AcuSolve. Then you have to validate your numerical result with the wind tunnel experiment result.

Heat Exchangers are widely used in most engineering fields, such as the process, power, automotive, cryogenics, refrigeration, air conditioning, heat recovery, manufacturing industries, etc. So, a lot of research is going on to develop and improve heat exchanger effectiveness. In this project, you are going to Analyze fluid flow in a heat exchanger using an analysis software and then compare the result data with the experimental result of a Heat Exchanger setup.

Want to develop practical skills on latest technologies? Checkout our latest projects and start learning for free

The aerodynamic properties of a cricket ball can greatly be affected by the prominence of the seam, the surface roughness of the ball in play, and the launch attitude of the ball by the bowler. Based on seam angle and surface roughness of the ball, an asymmetric airflow over the ball due to pressure difference can be generated thereby deviating the flight from the intended path. This potential flight deviation is called swing. Therefore, it is extremely important to understand the aerodynamic properties of used cricket balls as wear and tear can have a major effect on the swing. The primary objectives of this work were to understand the aerodynamic properties of a series of used cricket balls, thus the mechanism of swing as well as the drag of a cricket ball.

Fin is nothing but an extended surface found on the heat exchanging devices such as radiators in Car, Bike engines, Computer CPU heatsinks and Heat exchangers in power plants. An efficient Fin can really increase the performance of a system. There are various types of Fin and analyzing those theoretically takes a lot of effort. So, researchers around the world take help of numerical methods to analyze complex problem such as heat transfer through Fin. In this project, you will work on solving the various type of fin using numerical methods and compare it with a theoretical solution where it exists.

It is expensive to use physical experiments to get essential engineering data for designing is quite expensive. Getting engineering data of a fluid in motion, using Computational Fluid Dynamics (CFD) Simulations are relatively inexpensive. Costs are likely to be decreased as computational power has increased. So, using numerical methods to solve various flow problems is effective. In this project, you are going to solve a one-dimensional problem of interacting blast waves using the Finite Volume Method (FVM).

For any foundation work it is very much necessary to study the mechanical parameter of soil before the concreting starts. To study the parameters on the deep foundation works,

Thrust vectoring is one of the technologies used to overcome the challenge for innovation. By vectoring the exhaust jet, the engine’s thrust is used to control the aircraft. In supersonic fighter aircraft thrust vectoring is one of the major phenomena used for VTOL/STOL and maneuvering. But in commercial aircraft thrust vectoring is used to prevent catastrophic failure and for Short Take-Off and Landing.

The VELOCITY-XL aircraft is a long-range aircraft with the latest technology in aerodynamics and structure to provide good maneuverability facilities and stealth mode. This can move 1100-miles cross country trips at speeds above 190 MPH while carrying four adults and baggage in total comfort. These airplanes perform best at altitudes of 8,000-11,000 feet. Landing requires a speed of about 85 MPH and a 1,500 feet long landing strip.

ICEM is a software developed by ICEM CFD engineering which provides classy geometry tools for mesh generation, pre-processing and mesh optimization tools. It is used for manufacturing applications such as computational fluid dynamics and mechanical analysis.

A nozzle is a relatively simple device, just a specially shaped tube through which hot gases flow. The purpose of the nozzle, in subsonic flow, is to constrict the airflow, thus critically increasing the thrust as it leaves the engine.

The population on the earth is growing daily and likewise vehicles are also been increasing daily. The rate increase of the vehicles is been increasing considerably.

Project Description

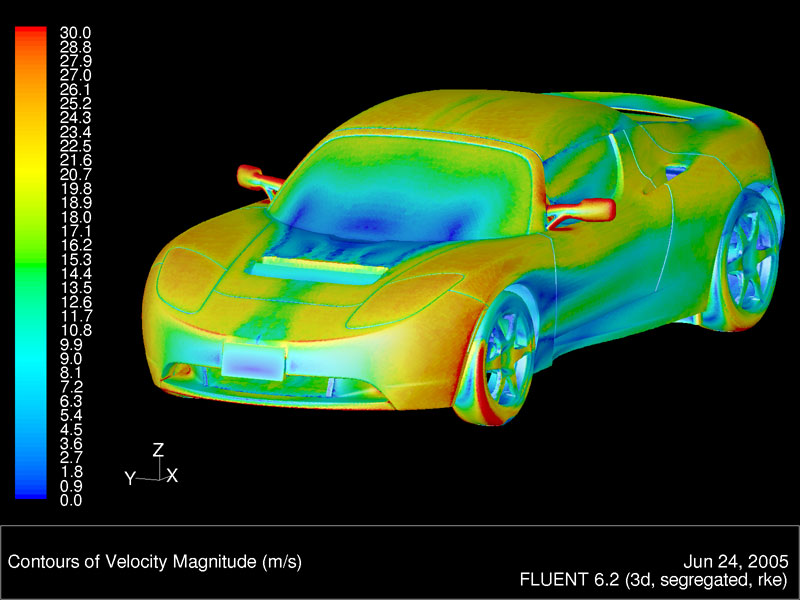

A decade ago aerodynamics was insignificant among commercial vehicle manufacturers. It had its application in aerospace industry and F1 or any other racing. Today more and more companies are focusing on aerodynamics of even the mid-range road vehicles. Researches have concluded that with proper optimization of aerodynamics, fuel efficiency improves.

In this project you will learn to use SIM SCALE, an online tool for performing the CFD analysis of a formula style racing car. SIM SCALE allows us to upload and perform analysis online so that we do CFD on even low end computers.

In this CFD project, you will use ANSYS to analyse the fluid flow and heat transfer in a mixing elbow. Mixing elbow is used in piping systems of power plants and process industries to find the flow field and temperature field in the region of the mixing section which helps to fix the position of inlet pipes.

Before starting the project here is an overview of the problem which we are going to solve - Now a cold fluid (20C) is going to enter through the large inlet and it is going to get mixed with the warmer fluid (40C) which enters through a smaller inlet at the elbow. For the flow at the large inlet, the Reynolds number is 50,800, hence the turbulent flow model will be needed.

INTRODUCTION:

The Reciprocating Compressor fins produced using Aluminum composite. It's given increment in contact territory in convective heat flow. Air cooling is a technique for dispersing heat. It works as an expanded progression of air over its surface. A blade is a surface that stretches out from an article to build the pace of heat flow. The point of the present work-study is to set up a limited component model of balance. We altered geometrical shapes of fins for analysis and select the most effective cooling fin.

INTRODUCTION:

Convective heat flows between surfaces. The encompassing has been a significant issue and a subject of study for quite a while. In this venture, the heat flow execution of blade reformed by ANSYS workbench. It discusses the structure of balance with different plan setup. The heat flow execution of fins temperature having a different geometry. In this investigation, Aluminium utilized as the base metal for the balance material. It is used for different arrangements. Different setups discussed with the help of CATIA programming Analysis. The balance execution is also done through the product ANSYS workbench.

INTRODUCTION:

A wing is a sort of balance with a surface that produces streamlined power for flight or drive through the climate, or through another vaporous or fluid liquid. A wing's streamline quality is like lift-to-drag proportion. The lift of a wing creates at a given speed and approach can be one to two significant degrees. It is more prominent than the complete delay in the aircraft wing. A high lift-to-drag proportion requires an altogether littler push to move the aircraft wing through the air at an adequate lift.

INTRODUCTION:

This Ansys project has outlined the FE model utilizing beam elements to represent road bicycles using Ansys. The model mimics two standard stacking conditions. First, the vertical consistency and sidelong firmness of outlines of the bicycle geometry task. And second, these attributes to an improved arrangement in these conditions. Small edges (490 mm) carry both vertical consistency and horizontal solidness. The shorter top cylinder length (525 mm) and head tube point (74.5°) brings the side stiffer casing. The enhanced qualities show an extensive improvement over the current edges. It shows a 13% increase in vertical and 15% lessening in horizontal re-location.

INTRODUCTION:

An interfacing pole of an IC motor exposed to complex unique stacking conditions. In this manner, it is a machine component that stands out for researchers. The CAD model is taking the measurements from a standard machine drawing coursebook. In the gas pressure, variety in the chamber of an IC motor. The cylinder powers determined for basic positions. MATLAB codes composed for this count. Altair Hyper mesh and Hyper view utilized for pre-handling and post-preparing of the model. The limited component examinations performed Altair Radios. The upgraded interfacing pole is 11.3% lighter than the first plan.

A device that is used to reduce pollutants and toxic gases in the exhaust gas from the combustion engine by chemical reactions is known as a catalytic converter. These converters need a temperature of 426-degree centigrade so that it can convert harmful gases into non-toxic gases, so these are placed as close as possible to the engine to get enough temperature which it requires.

These converters are mostly used in automobiles, but their application has also been increased in mining equipment, generators, etc. where the amount of harmful gas emission is high.

For analysis of the catalytic converter, Ansys has a different software which is FEA (Finite Element Analysis) followed by CFD Analysis by which we can know how efficient the converter is.

The method which uses vacuum to deposit materials that produce high-performance, high-quality solid materials is known as chemical vapor deposition. CVD is mostly applied in semiconductors manufacturing to coat/ produce thin films. CVD has become the most versatile and important method to synthesize any product.

In CVD, mostly water is used as a substrate and is exposed to one or more volatile presses which then reacts and deposits on the surface of the desired product. CVD widely produces microfabrication to deposit various materials like Si, C, W, etc. which are good conductors.

The main step in CVD is to study the properties of the material which has to be deposited and the properties of the substrate on which it has to be deposited.

To know about the vapor deposition on a substrate, Ansys has a separate software called Computational Fluid Dynamics software ANSYS/FLUENT is used.

Centrifugal blower was designed mainly to handle air and gases which are compressible fluids. A blower contains more than one stage of compression which is mounted on a single shaft. Blowers are mostly used in power stations, ventilation, workshops, etc.

A centrifugal compressor can be related to a fan-based on the type of application which it has been applied to. For the simulation of a centrifugal blower, Ansys’s CFD simulation software helps to analyze and give the result which is required.

In brakes, the main property is the thermal conductivity as a lot of heat is generated in the brakes when it is applied. So, the brakes must be strong enough to control or dissipate the heat and to stop the vehicle with minimum displacement in urgent situations.

The main property of the brake is that it should cool down rapidly to avoid any structural imbalances to the brakes and another thing is that it should clean itself automatically.

Disc brake slows the rotatory motion of the wheel by the abrasion of brakes pads onto the wheel. During braking, kinetic energy is converted into heat energy, which heats the air present in between the brakes by which the durability of the brakes increases.

Finite element analysis helps in numerically solving any engineering problem. FEA represents every engineering problem in a numerical way by which the solution to the problems can be known and whether the process is feasible or no can be known.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

Want to develop practical skills on latest technologies? Checkout our latest projects and start learning for free

Join 250,000+ students from 36+ countries & develop practical skills by building projects

Get kits shipped in 24 hours. Build using online tutorials.

Stay up-to-date and build projects on latest technologies